For some time I’ve been meaning to learn the skills necessary to fabricate custom PCBs at home. This is been on my to do list literally for years, since childhood in fact. Recently a project came up that gave me an opportunity to put the final pieces of the puzzle together and finally get off my butt and build something. No one else in the world will find this as jaw-droppingly fascinating as I do, but nonetheless here it is.

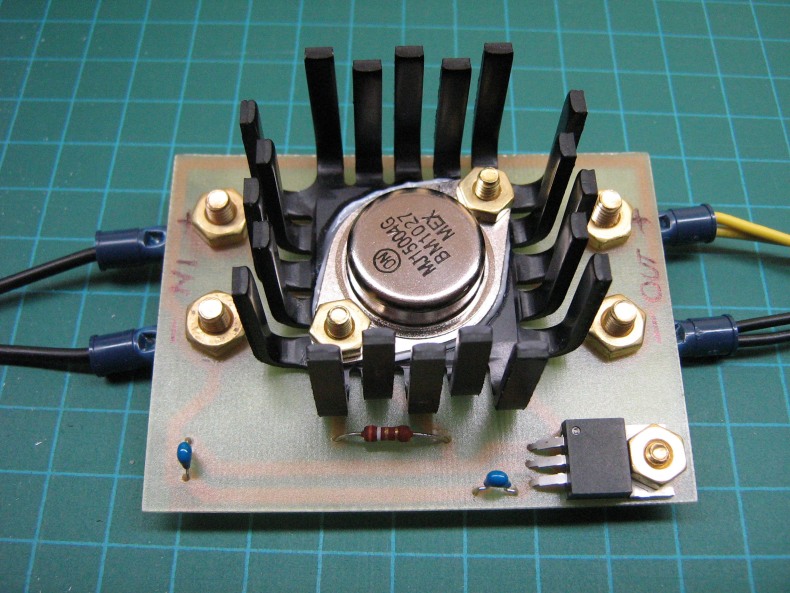

This is a 12 volt voltage regulator, it’s designed to handle 15 A but since I don’t quite know what I’m doing it needs a little tweaking to get there.

But I’m not really into talking about the circuit today, it’s etching the board that I’m gleeful about today. The entire process needs some refinement, I’ve used 1/16 inch 1 ounce board stock, since 15 A is the target 2 ounce copper may be more appropriate but since it took almost 2 hours to etch I’m happy with the 1 ounce at this point. I used homemade copper chloride etchant, it also needs some refinement in addition to the 2 hour etch time, the colors isn’t right, too dark.

I’m very happy with the final result, however there’s numerous faults to pick on. There are brown stains on the copper in numerous locations, this is where the etchant was beginning to break through the resist, not the end of the world but something that needs attention. I don’t currently have a plan to control the tarnish on the bare copper, I’d like my boards to be shiny in the future. There’s also a routing issue here, the upper two terminals are connected by a trace running around the lower perimeter of the board, this is ground. The lower two terminals which reach across the bare ground trace are positive, obviously this is not ideal. On this board I’m using traces 2 mm wide, these work very well but I suspect if I where using the much finer traces common today, I would not have had nearly as good luck.

But that’s all solutions for another day. Today I designed it, etched it, populated it, powered it up and it worked, no explosions. I’m pretty happy with that.